Project Preparation

We offer two methods of project preparation. First method is by using your own artwork and the second method is by having us design it for you. If you would like to use your own artwork, we would like to point out some of the basic requirements in regards to the business card design.

We offer two methods of project preparation. First method is by using your own artwork and the second method is by having us design it for you. If you would like to use your own artwork, we would like to point out some of the basic requirements in regards to the business card design.

The business cards are created in two standard formats: ISO EU 85.5 x 54 (mm) – credit card size & 3.5 × 2 in (88.9 x 50.8 mm) – standard US business card size. There are of course custom sizes available which we can produce – like Japan style . Each card can also be in two standard shapes: square edged or rounded edges.

The thickness of business cards is available in several standard sizes: 0.4mm – similar to a regular cardstock (most common), 0.76mm – similar to the thickness of a credit card.

The thickness of business cards is available in several standard sizes: 0.4mm – similar to a regular cardstock (most common), 0.76mm – similar to the thickness of a credit card.

PCV business cards are made from synthetic plastic (polyvinyl chloride). They are strong, durable, and resistant to water. The print is permanent and UV resistant.

Prior to the business card design, it is very important to decide on the technical aspect of the business card. Transparent business cards require one-sided design.

Prior to the business card design, it is very important to decide on the technical aspect of the business card. Transparent business cards require one-sided design.

The design visible from the front will also be visible from the back as a mirror image. Full color PVC business cards can have double sided design as they are not transparent. Another very important technical aspect is determining the number of colors that a card will have.

There are no limits, but the number of colors drive the cost, meaning the more colors the more expensive a card will be. The most expensive option is a full color option. The least expensive option is using a single color.

Here are some of the industry standard parameters and key words: 4+4 – double sided business card in full color, 4+1 – full color front and mono color back, 4+0 – one sided business card with full color front and white back. Colors are encoded using CMYK color palette (C – Cyan, M – Magenta, Y – Yellow, K – Black).

Here are some of the industry standard parameters and key words: 4+4 – double sided business card in full color, 4+1 – full color front and mono color back, 4+0 – one sided business card with full color front and white back. Colors are encoded using CMYK color palette (C – Cyan, M – Magenta, Y – Yellow, K – Black).

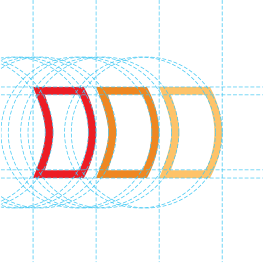

Print quality DPI plays an important role. The minimum resolution we recommend is 300dpi. Safe area is between 3 to 5mm. It is important that no logo or text extends over this area around the card. Bleed area is the area that may be cut off during preparation of business cards to their native form.

Your graphic should extend over the bleed area, such as a background color. However, a logo or text cannot as it will be cut out. The purpose of bleed area is the look of uniform color even at the very edge of the card. If your design features non-standard fonts, we will need these in order to prepare the artwork for production.

The final artwork should be submitted in PDF or TIFF format which will guarantee the best quality.

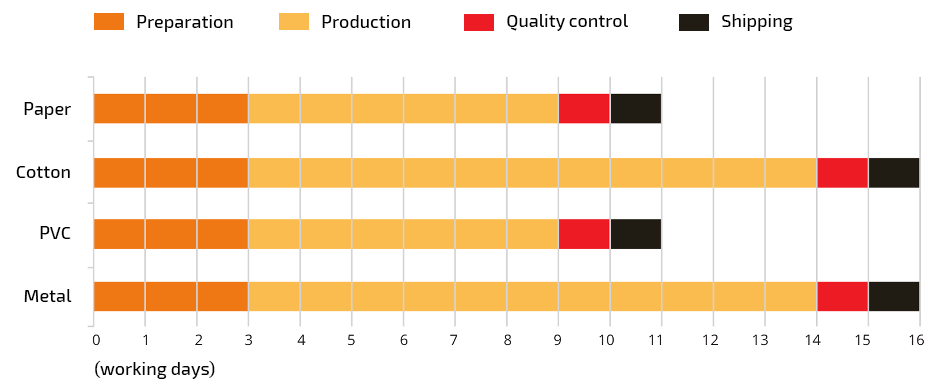

Production and turnaround time

You want to get your business cards quickly. Maybe you have an important upcoming business meeting or conference. Below is a table that shows turnaround time for all our products. Quality is most important to us; therefore, please choose the right type of business card in regards to lead time.

The following are typical and average turnaround times.

Design

When we work on your graphic design, we always want the process to go as smoothly as possible. However, often times the graphic design takes considerable more time.

We assume the smooth process when a client already has some graphic elements such as logo. In this case we can assume the design process to take between 1 to 3 business days. If logo design is necessary, the design process can take as long as 5 business days.

For more information, please click here.

Production

When you are satisfied with the results of the design of your business card the production process starts. The production phase once started, cannot be interrupted and no more changes to the graphic design are allowed.

When you are satisfied with the results of the design of your business card the production process starts. The production phase once started, cannot be interrupted and no more changes to the graphic design are allowed.

During this phase, we utilize our experience as well as traditional manual approach to business card creating using latest technologies. This is the most time consuming process and the time depends on the material used as well as complexity of the project.

Quality Control

As high quality is our top priority, every business card undergoes quality control before it is packed and shipped to our customers.

As high quality is our top priority, every business card undergoes quality control before it is packed and shipped to our customers.

After production, we check for scratches, paint fades, chips and any other defects. If defective cards are found, they are replaced and the order is packed and ready to ship.

Shipping

All domestic shipments are shipped using FedEx ground or FedEx express. All international shipments are shipped using DHL Express or USPS.

Comparison of Business Card parameters

| Paper Cards | Duplex & Triplex Cards | Letterpress Cards | Full Color Plastic Cards | Translucent Plastic Cards | Metal Cards | |

|---|---|---|---|---|---|---|

| DURABILITY | Medium | High | Medium | Very High | Very High | Highest |

| MATERIAL | Paper | Paper & paperboard | Cotton Stock | synthetic plastic polymers | synthetic plastic polymers | stainless steel |

| MATERIAL COLOR | We can use various colors of paper, which we will select according to your preferences. | We can use various colors of paper, which we will select and combine according to your preferences. | High White, Natural Warm White, Gray, Black | Satin White Completely black (special orders) | Semi-transparent Clear transparent (special orders, limited durability) | Native metal color 0.3mm (300 micron) |

| THICKNESS | Weight 230 - 400 g/cm classic paper business card standard | Weight 600-1200 g/m² depending on the number of layers, usually not more than 1.3 mm (70 pt) | Weight 350-800 g/m² Appx. thickness 0.8-1 mm (60pt) | 0.5mm (500 micron) 0.76mm (760 micron) | 0.5mm (500 micron) 0.76mm (760 micron) | Special orders 0.5 / 0.7mm |

| STIFFNESS | Low / Medium | Very High | Medium | Very High | High or medium (depending on the thickness) | Very High |

| HOT STAMPING | Yes | Yes | Yes | Yes | Yes | No |

| UV SPOT GLOSS | Classic 2-side & special 3D version | Yes | Yes (with limitations) | Classic 2-side | Special orders | with limitations |

| SILKSCREEN PRINT | Yes | Yes | Yes (special orders) | Yes (underprint & Pantone spot) | Yes (metallic or white underprint & Pantone spot) | Yes (metallic, white & Pantone spot) |

| PANTONE COLORS | Yes | Yes | Yes, Uncoated | Yes, Coated | Yes, Coated | Yes, Coated |

| EMBOSSING & DEBOSSING | Yes | Yes | Yes | with limitations | with limitations | Yes (etching & engraving) |

| DIE CUT & LASER CUT | Special orders | Special orders | Special orders (with limitations) | No | No | Yes |

| EDGE COLOR | in the colour of the paper chosen | Edge Gliding (metallic foil) | Edge Gliding (metallic foil) or Edge Painting | in the colour of the surface chosen | in the colour of the surface chosen | in the colour of the surface chosen |

| CARD SURFACE | Matte, Glossy | Matte, Glossy, Metallic glitter | natural cotton paper surface | Matte, Glossy | Smooth matte Frosted finish | Glossy metallic mirror matte / with subtle texture |

| offset & digital print | letterpress, digtal & offset print | Letterpress (Pantone colors) | digital print | digital & silkscreen print | CMYK DIGITAL PRINT & SILKSCREEN | |

| PRINT SAFETY / FINISH | soft silk matte or glossy finish | optional soft silk matte finish | none | satin or glossy finish | satin or glossy finish | not needed, stainless |

| EXCLUSIVITY INDEX | High | Highest | Highest | High | High | Highest |